Reducer maintenance

时间:2018-10-27 16:17 tags: Press Room

XNUMX. Start maintenance:

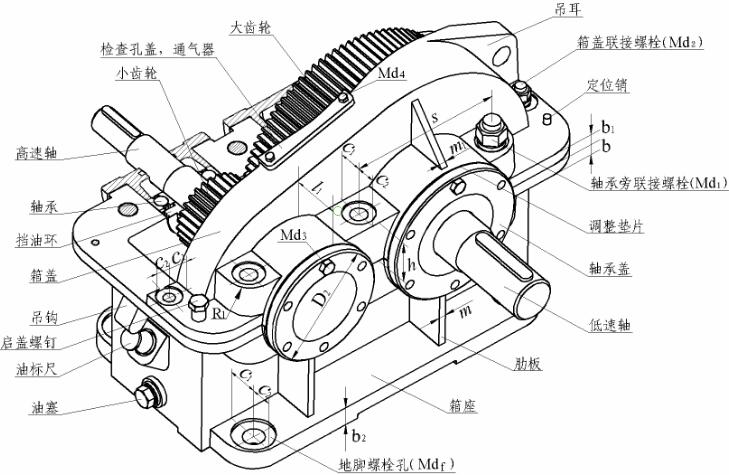

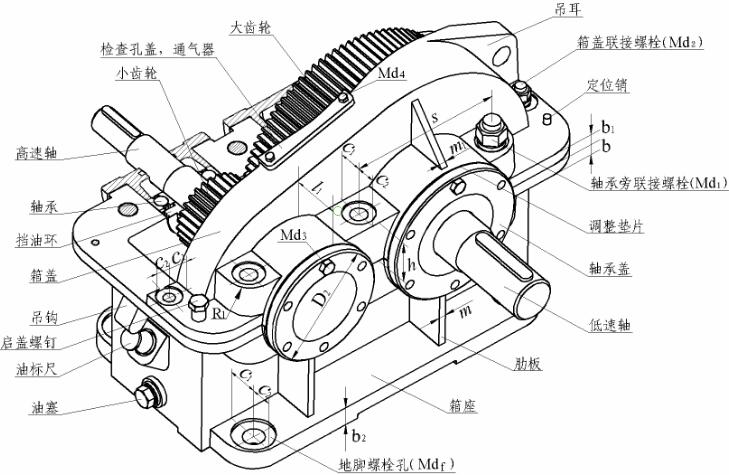

1. Disassemble the machine, gradually disassemble according to the equipment structure, and make detailed records to prevent mixed parts;

2. Clean the gear box body and check for oil leaks;

3. Inspect and measure the gears in the reducer, focus on checking the wear and meshing status of the gears, and record the inspection results;

4. Measure the bearing clearance, check the wear condition, measure the shell, check the wear condition, and record the inspection results;

5. Measure the input, output and intermediate shaft of the reducer, check the wear and tear, and record the inspection results;

6. Summarize the above inspection results, summarize various dimensional deviations, and determine repair items;

XNUMX. Overhaul process operation flow:

1. Disassemble the reducer:

(1) Descale the outer surface of the disassembled reducer housing, and then clean it with kerosene;

(2) Release the lubricating oil in the reducer;

(3) Use special tools (pull puller) to remove the reducer pulley;

(4) Disassemble the output part of the reducer, remove the end cover fastening screws, separate the end cover with a jack wire or a crowbar, and then use a puller and a bearing press to remove the gears and bearings on the output shaft;

(5) Use the same method to remove the input shaft, gear, and bearing of the input part;

(6) Remove the intermediate shaft, gear and bearing by pressing with a bearing press or knocking with a copper rod;

(7) Clean the parts removed above with kerosene;

(8) Inspect and measure the removed gears, bearings, shafts, end covers, shells, and bearing holes, and record the dimensions in detail;

2. Check and repair bearings:

(1) Remove the bearing with a puller or a bearing press, and clean it with kerosene;

(2) Check the wear condition of the bearing, shake the bearing, measure the shaft and radial clearance (0.02-0.2mm), turn to the bearing to listen to the sound, check the degree of wear of the ball and groove surface, whether there are spots and annealing conditions, serious To be replaced with a new one;

(3) Check and use a micrometer to measure the gap between the bearing and the shaft installation joint, and record the measurement result. The outer circle of the conventional matching size should be added by 0.02-0.05mm, and it should be repaired if it exceeds the range;

(4) The new bearing must be kept clean before assembling;

(5) For bearings that need to be filled with grease, the filling amount should be half of the bearing cavity;

(6) When assembling the bearing by the press-in method, a special sleeve or rod must be used between the presser and the bearing body, and the same shall be used for knocking installation to avoid damage to the bearing;

(7) The end faces of the inner and outer rings of the bearing should generally be close to the shaft shoulder and the inner hole shoulder. The tapered and thrust bearings are generally not greater than 0.05mm, and the others are not greater than 0.1mm;

(8) After the bearing is installed, the outer circle and the inner hole of the shell should contact evenly, and the general interference is between 0.02-0.05mm;

(9) When using oil heating or bearing heater to heat the bearing, the temperature should not be higher than 120℃;

(10) For bearings that have no installation direction, the end printed with the model number should be outward for easy viewing;

(11) Assemble radial non-adjustable radial bearings at both ends of the shaft, and when the axial displacement is limited by the glands at both ends, one end is tight, and the other end must have an axial gap: the calculation formula is as follows:

C=0.000011×(80-t)L﹢0.15 (where L is the shaft length and t is the room temperature)

(12)角接触轴承轴向游隙一般为0.04—0.1mm,圆柱(圆锥)滚子轴承轴向游隙一般为0.05—0.18mm;

3. Maintenance of gear shaft:

(1) There is a puller and a press to remove the gear and clean it;

(2) Measure the gear radial runout, the allowable range is: 0.02-0.05mm;

(3) Observe the wear of the gear tooth surface and whether there is deformation, annealing, spots, peeling, etc.;

(4) The ones with severe wear and measuring size exceeding the allowable range should be replaced;

(5) When assembling a new gear, the gear hole and shaft must meet the requirements, the gear reference surface and the shaft shoulder (or the end surface of the positioning sleeve) should fit together, and the gear reference surface should be perpendicular to the axis;

(6) The axial misalignment of mutually meshing cylindrical gear pairs should meet the standard. When the tooth width B≤100 mm, the axial misalignment should be less than 0.05B, and when B≥100mm, the axial misalignment should be less than 5mm;

(7) Bevel gears should be installed according to the matching number of machining;

4. Overhaul of reducer housing:

(1) First, clean the inside of the shell with kerosene to observe whether there are cracks or shedding;

(2) Use a dial indicator to measure the inner hole size of the assembled bearing in the shell and make a record. Generally, the ovality and taper should be less than 0.03mm, and the inner diameter should be less than zero line 0—0.02mm (normal bearing outer circle size tolerance is zero line) ;

(3) The shell that is out of tolerance or damaged should be repaired or replaced;

(4) All parts and components of the reducer should be cleaned during installation, and the assembly sequence is reverse to that during disassembly;

(5) Install the output part and apply oil or detergent to the outer surface of the shaft. After the bearing is pressed into the shaft, the inner ring of the bearing must be close to the shaft shoulder or positioning sleeve, and the gap should not be greater than 0.05mm;

(6) When the gear is installed, the clearance between the gear end face and the shaft shoulder should not be greater than 0.1mm;

(7) The oil baffle should be flat and intact. After the inner ring and the shaft are set, the outer ring and the box body must maintain a certain gap (2-3mm);

(8) To install the intermediate shaft, first press the bearing at the fixed end into the shell, then put the gear and the intermediate spacer in order, and finally press the shaft with the other end of the bearing to check the keyway of the lower gear and press it into place.Measure the size of the end face of the fitting gland and the outer ring of the bearing. The gap is generally: C=0.000011×(80-t)L﹢0.1 (where L is the shaft length and t is the room temperature);

(9) To install the input part, first install the gland at the fixed end, press in the bearing at this end, then put the gear and spacer in order, and then press in the shaft with the bearing at the other end.Measure the size of the other end, and the normal axial run-out gap of the gland is not more than 0.05-0.1mm;

(10) Gear contact spots are not less than 45% along the tooth height direction, and not less than 60% along the tooth length direction. The contact is uniform and the position is close to the middle part of the tooth surface;

(11) Add new oil to the reducer, the grades should be unified, and should not be mixed, and the oil level should be in the middle of the observation hole of the scale;

(12) Then press in the pulley, and the fixing bolt must be equipped with anti-return pad or anti-bolt lock plate;

(13) The joint surface of the shell must be coated with sealant, and the tightening torque of the fastening bolts should meet the following standard values:

M10 50Nm M12 80Nm M16 190Nm M20 420Nm

M24 650Nm M30 1300Nm M36 2300Nm

(14) Drain all the old oil during the maintenance and oil change of the reducer. The oil change interval time sequence should be: 500h for the first time, 3 months for the second time, 6 months for the third time, and 1 for the fourth time. year;

1. Disassemble the machine, gradually disassemble according to the equipment structure, and make detailed records to prevent mixed parts;

2. Clean the gear box body and check for oil leaks;

3. Inspect and measure the gears in the reducer, focus on checking the wear and meshing status of the gears, and record the inspection results;

4. Measure the bearing clearance, check the wear condition, measure the shell, check the wear condition, and record the inspection results;

5. Measure the input, output and intermediate shaft of the reducer, check the wear and tear, and record the inspection results;

6. Summarize the above inspection results, summarize various dimensional deviations, and determine repair items;

XNUMX. Overhaul process operation flow:

1. Disassemble the reducer:

(1) Descale the outer surface of the disassembled reducer housing, and then clean it with kerosene;

(2) Release the lubricating oil in the reducer;

(3) Use special tools (pull puller) to remove the reducer pulley;

(4) Disassemble the output part of the reducer, remove the end cover fastening screws, separate the end cover with a jack wire or a crowbar, and then use a puller and a bearing press to remove the gears and bearings on the output shaft;

(5) Use the same method to remove the input shaft, gear, and bearing of the input part;

(6) Remove the intermediate shaft, gear and bearing by pressing with a bearing press or knocking with a copper rod;

(7) Clean the parts removed above with kerosene;

(8) Inspect and measure the removed gears, bearings, shafts, end covers, shells, and bearing holes, and record the dimensions in detail;

2. Check and repair bearings:

(1) Remove the bearing with a puller or a bearing press, and clean it with kerosene;

(2) Check the wear condition of the bearing, shake the bearing, measure the shaft and radial clearance (0.02-0.2mm), turn to the bearing to listen to the sound, check the degree of wear of the ball and groove surface, whether there are spots and annealing conditions, serious To be replaced with a new one;

(3) Check and use a micrometer to measure the gap between the bearing and the shaft installation joint, and record the measurement result. The outer circle of the conventional matching size should be added by 0.02-0.05mm, and it should be repaired if it exceeds the range;

(4) The new bearing must be kept clean before assembling;

(5) For bearings that need to be filled with grease, the filling amount should be half of the bearing cavity;

(6) When assembling the bearing by the press-in method, a special sleeve or rod must be used between the presser and the bearing body, and the same shall be used for knocking installation to avoid damage to the bearing;

(7) The end faces of the inner and outer rings of the bearing should generally be close to the shaft shoulder and the inner hole shoulder. The tapered and thrust bearings are generally not greater than 0.05mm, and the others are not greater than 0.1mm;

(8) After the bearing is installed, the outer circle and the inner hole of the shell should contact evenly, and the general interference is between 0.02-0.05mm;

(9) When using oil heating or bearing heater to heat the bearing, the temperature should not be higher than 120℃;

(10) For bearings that have no installation direction, the end printed with the model number should be outward for easy viewing;

(11) Assemble radial non-adjustable radial bearings at both ends of the shaft, and when the axial displacement is limited by the glands at both ends, one end is tight, and the other end must have an axial gap: the calculation formula is as follows:

C=0.000011×(80-t)L﹢0.15 (where L is the shaft length and t is the room temperature)

(12)角接触轴承轴向游隙一般为0.04—0.1mm,圆柱(圆锥)滚子轴承轴向游隙一般为0.05—0.18mm;

3. Maintenance of gear shaft:

(1) There is a puller and a press to remove the gear and clean it;

(2) Measure the gear radial runout, the allowable range is: 0.02-0.05mm;

(3) Observe the wear of the gear tooth surface and whether there is deformation, annealing, spots, peeling, etc.;

(4) The ones with severe wear and measuring size exceeding the allowable range should be replaced;

(5) When assembling a new gear, the gear hole and shaft must meet the requirements, the gear reference surface and the shaft shoulder (or the end surface of the positioning sleeve) should fit together, and the gear reference surface should be perpendicular to the axis;

(6) The axial misalignment of mutually meshing cylindrical gear pairs should meet the standard. When the tooth width B≤100 mm, the axial misalignment should be less than 0.05B, and when B≥100mm, the axial misalignment should be less than 5mm;

(7) Bevel gears should be installed according to the matching number of machining;

4. Overhaul of reducer housing:

(1) First, clean the inside of the shell with kerosene to observe whether there are cracks or shedding;

(2) Use a dial indicator to measure the inner hole size of the assembled bearing in the shell and make a record. Generally, the ovality and taper should be less than 0.03mm, and the inner diameter should be less than zero line 0—0.02mm (normal bearing outer circle size tolerance is zero line) ;

(3) The shell that is out of tolerance or damaged should be repaired or replaced;

(4) All parts and components of the reducer should be cleaned during installation, and the assembly sequence is reverse to that during disassembly;

(5) Install the output part and apply oil or detergent to the outer surface of the shaft. After the bearing is pressed into the shaft, the inner ring of the bearing must be close to the shaft shoulder or positioning sleeve, and the gap should not be greater than 0.05mm;

(6) When the gear is installed, the clearance between the gear end face and the shaft shoulder should not be greater than 0.1mm;

(7) The oil baffle should be flat and intact. After the inner ring and the shaft are set, the outer ring and the box body must maintain a certain gap (2-3mm);

(8) To install the intermediate shaft, first press the bearing at the fixed end into the shell, then put the gear and the intermediate spacer in order, and finally press the shaft with the other end of the bearing to check the keyway of the lower gear and press it into place.Measure the size of the end face of the fitting gland and the outer ring of the bearing. The gap is generally: C=0.000011×(80-t)L﹢0.1 (where L is the shaft length and t is the room temperature);

(9) To install the input part, first install the gland at the fixed end, press in the bearing at this end, then put the gear and spacer in order, and then press in the shaft with the bearing at the other end.Measure the size of the other end, and the normal axial run-out gap of the gland is not more than 0.05-0.1mm;

(10) Gear contact spots are not less than 45% along the tooth height direction, and not less than 60% along the tooth length direction. The contact is uniform and the position is close to the middle part of the tooth surface;

(11) Add new oil to the reducer, the grades should be unified, and should not be mixed, and the oil level should be in the middle of the observation hole of the scale;

(12) Then press in the pulley, and the fixing bolt must be equipped with anti-return pad or anti-bolt lock plate;

(13) The joint surface of the shell must be coated with sealant, and the tightening torque of the fastening bolts should meet the following standard values:

M10 50Nm M12 80Nm M16 190Nm M20 420Nm

M24 650Nm M30 1300Nm M36 2300Nm

(14) Drain all the old oil during the maintenance and oil change of the reducer. The oil change interval time sequence should be: 500h for the first time, 3 months for the second time, 6 months for the third time, and 1 for the fourth time. year;

- Previous:Sales reducer company

- Next:Why is the reducer shell electrified